The HeatShield Protection

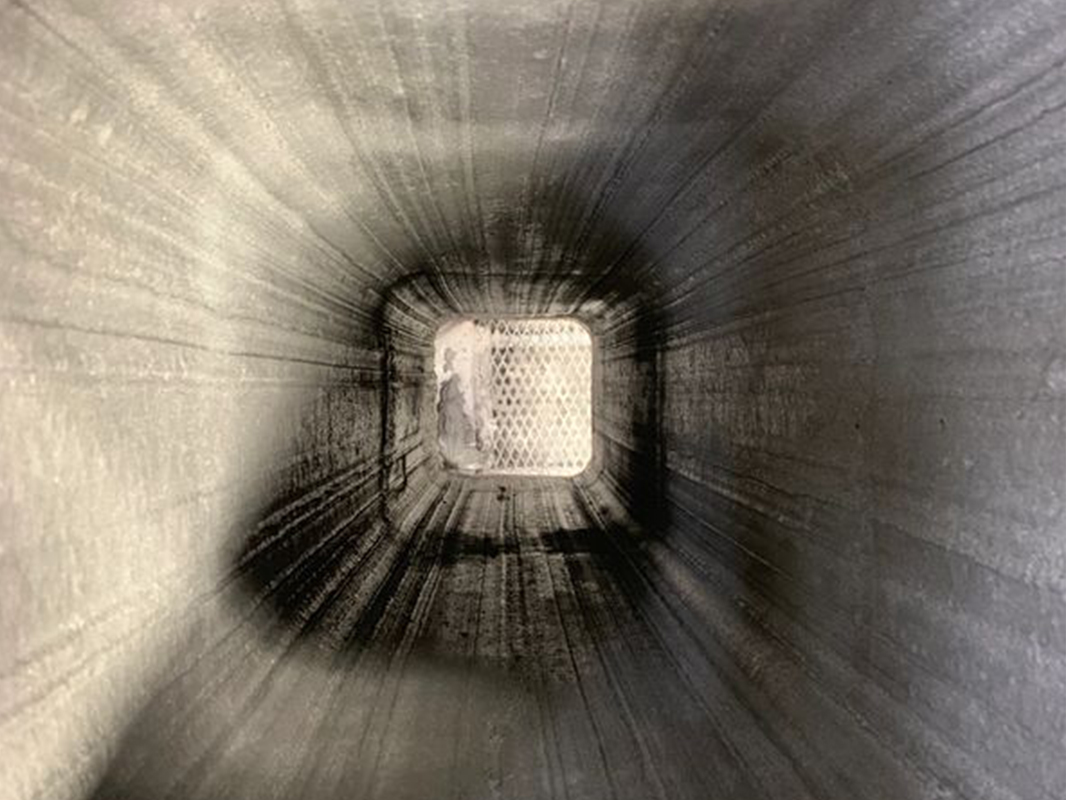

Step 1

The first step to repair using HeatShield products is a comprehensive inspection including evaluation the current condition of your chimney internals with our Chim-Scan camera system.

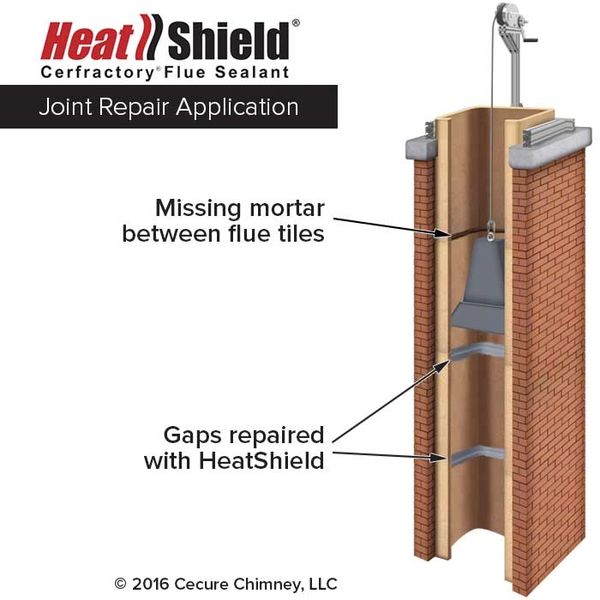

Chimney Mortar Joint Repair

With our Joint Repair system, your chimney is fixed right the first time. First, a special foam applicator blade is custom made to fit your chimney. The applicator tool is then positioned below each gap or void. The HeatShield Cerfractory Flue Sealant mixture is added. Each void in your flue is filled as the HeatShield mixture is extruded into the void by the tool. Your repaired void is made smooth as the tool is pulled upward.

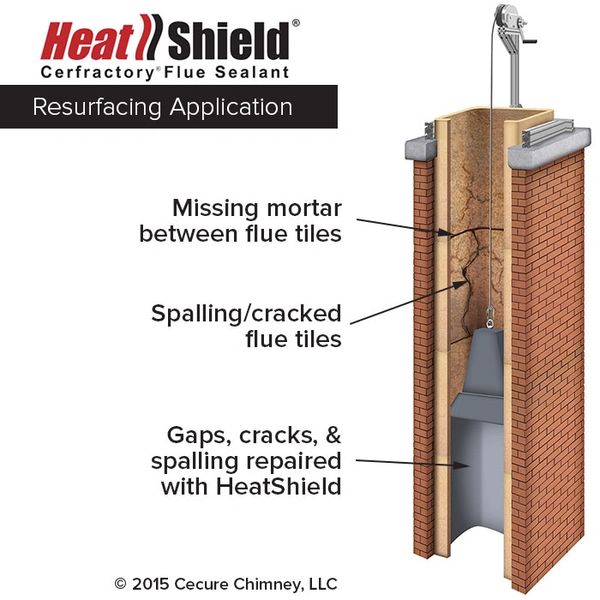

Resurfacing

For chimneys with cracked or spalled flues that are otherwise sound, the Resurfacing System is used to apply a coating over the entire flue. Cameras are used to verify repairs.

To restore your chimney’s flue by resurfacing the interior, a custom-made foam applicator plug is placed at the bottom of the flue and attached to a winch on top of the chimney.

First, a “tie coat” material is applied to the flue walls as the plug is pulled upward by the winch. The “tie coat” cleans any remaining dust in your flue and acts as a primer for the HeatShield Cerfractory Flue Sealant.

After the tie coat dries, the HeatShield material is then applied onto the flue at a thickness of about ¼” with the foam plug as it is pulled upward by the winch. This unique application method is known as “slip casting” or “slip cast extrusion”.

Prior Heat Shield Repairs Performed

The Chimney Safety Institute of America recommends that open masonry fireplaces should be swept at 1/8″ of sooty buildup, and sooner if there is any glaze present in the system. This is considered to be enough fuel buildup to cause a chimney fire capable of damaging the chimney or spreading to the home. Factory-built fireplaces should be swept when any appreciable buildup occurs. The logic is that the deposit is quite acidic and can shorten the life of the fireplace.

Schedule An Inspection

Call (904) 678-1790 Or Click the Link To the Right to Schedule Your Next Service Right Away